Robotic Pipeline Inspections for Industrial Sewer, Water & Utility Networks

Powered by AI

Facing blockages, unexplained losses, or pipeline-integrity issues?

Our advanced underground pipeline inspection services help you monitor your pipeline health for ensuring risk-mitigation and compliance.

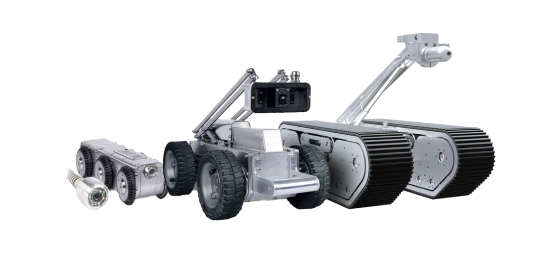

We are a leading robotic pipeline inspection company in India, specializing in water, sewer, stormwater drain, and industrial pipeline inspections. With a strong R&D backbone, we design and manufacture advanced robotics for blockages, contaminations, condition assessment, and tackling other complex underground infrastructure challenges.

Our AI-powered defect detection software identifies cracks, corrosion, blockages, and intrusions with high accuracy.

We serve industrial pipeline systems across sectors like Automotive, pharmaceuticals, chemical, food and beverages, and many others, offering precise, and actionable underground pipeline inspection solutions. Our inspection capabilities span acoustic and vibration-based condition assessment, sonar-enabled internal geometry mapping, and Ground Penetrating Radar (GPR) for locating and assessing enclosed WASH infrastructure. By combining sound-based and electromagnetic inspection methods, we deliver end-to-end visibility across internal pipe condition and external underground context.

HVAC Lines

Difficulty in access makes maintenance of HVAC Lines even more difficult. But our robotics are more than capable of navigating such lines and helping you locate problems before they become big.

Fire Hydrants

Due to their criticality, Fire Hydrants need a supply network that won't fail even in worst-case scenarios. Through Leak Detection and Conditional Assessment, we help you ensure network integrity.

Ad Hoc Maintenance

Below the ground, between the walls, or above the ceiling. Any pipe that’s a key part of your infrastructure can be inspected and maintained with the help of our robotic services.

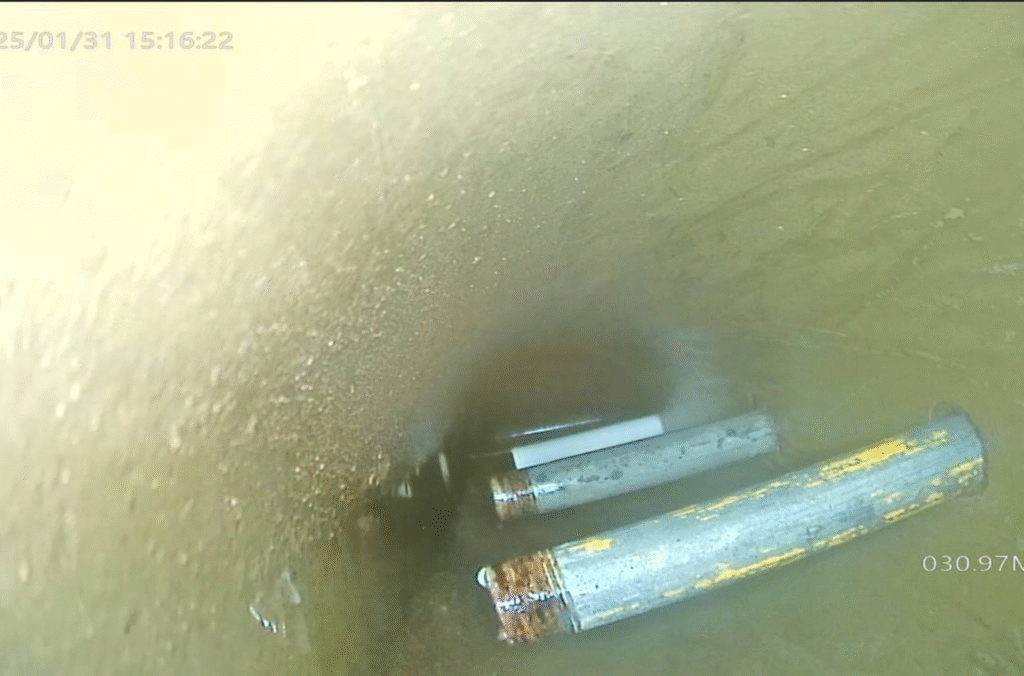

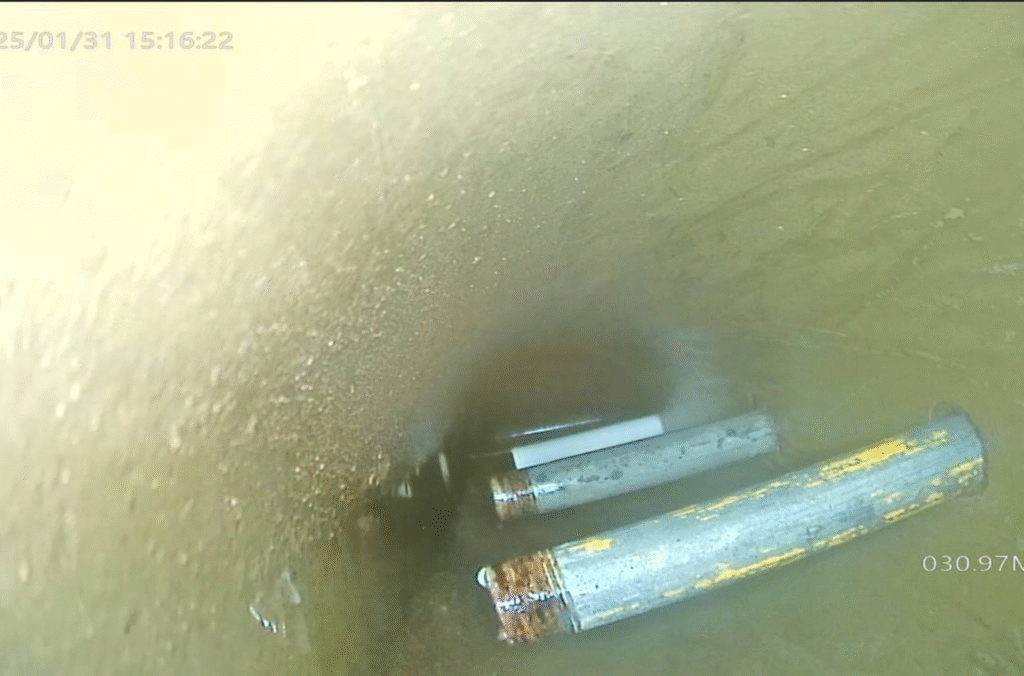

Blockage Detection

Blockage detection is key in sewers for preventing backups, overflow, flooding, contamination, and many other issues. Like its Water counterparts, the Endobot250 too is built to navigate the terrain it’s meant for, no matter the obstacle in front of it. Solid ergonomics and a six-wheel drive allow for smooth traversal even in the thickest of sludges.

Condition Assessment

Complexity of factors affecting structural degradation and length of sewer networks make condition assessment even more important. Together, Endobot250 and Swasth AI can give you a full overview of your network’s health, right from structural integrity to level of toxic gases.

Post-desilting Check

Desilting is a complex process. This is true especially from an operations perspective, because if desilting isn’t executed as intended, sewer networks will continue to face flow issues. That’s where the Endobot250 and its manoeuvring capabilities come in; to ensure that desilting projects have been carried out properly before the network is made operational.

Pre-commissioning Audit

Test runs are crucial to confirm the functionality of new sewer networks. But ensuring this is hard. These networks involve multiple phases of construction and years of workmanship, and aspects like gradient are hard to measure. For such scenarios, the Endobot250 comes with additional sensor options for Gradient Measurement and Laser Profiling.

Leak Detection

Despite being small, pipeline leaks can become process bottlenecks and affect operational costs. That’s why the quick, accurate leak-pinpointing abilities of Endobot90 and Endobot120 are key for keeping leaks in your supply pipelines in check.

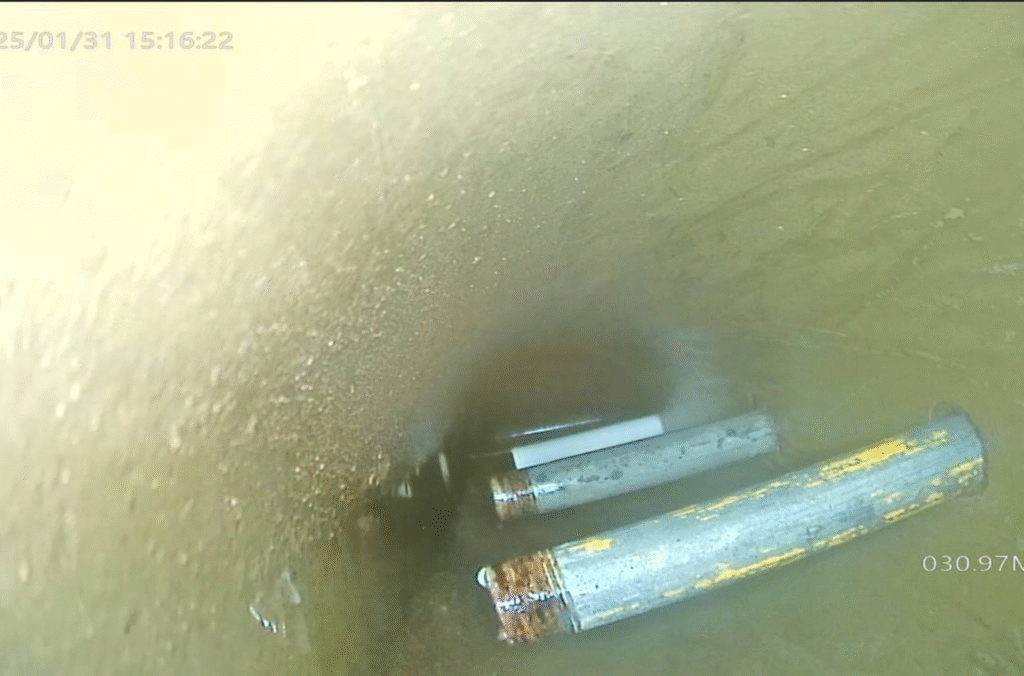

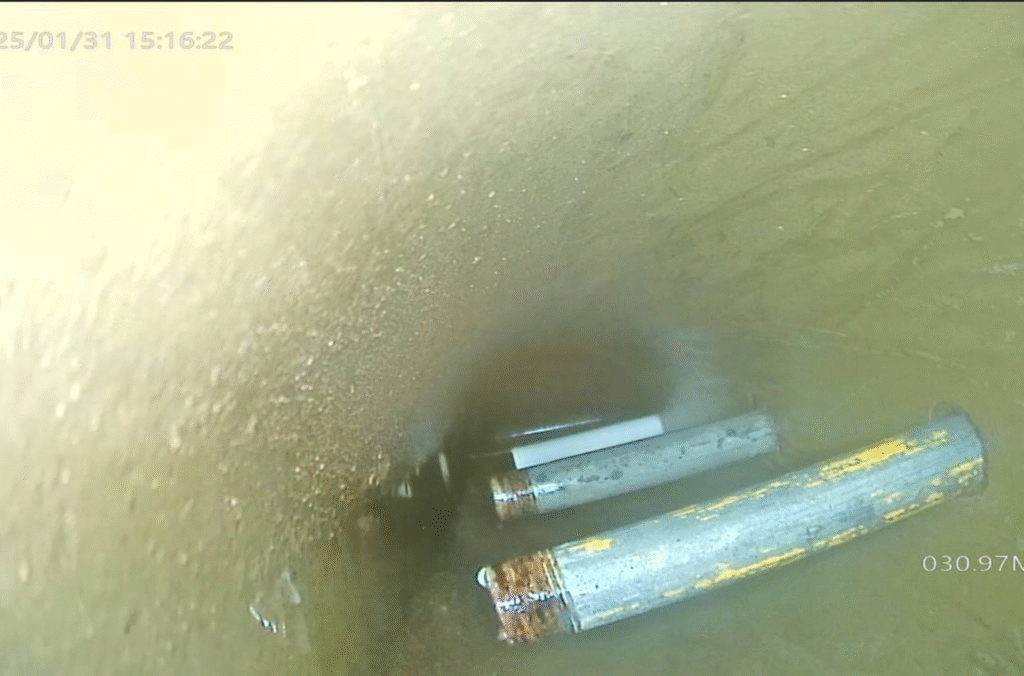

Contamination Check

Contaminations are hard to locate. Left unchecked, they can drastically impact supply-transmission quality, or turn into a network-wide issue. That’s why the imaging and processing power of the Endobot Water line-up are the perfect safeguards against contamination issues.

Illegal Connections

Illegal connections not only affect supply pressure, but also can have long-term impacts on the structural integrity of connections. That’s why the Endobot water line-up comes equipped with sensors for laser profiling and gradient measurement.

Blockage Pinpointing

Blockage is the most common problem that disrupts flow in supply pipelines. When left unchecked, they not only create transmission issues, but can impact the overall network by creating pressure differentials. But with the Endobot Water line-up, pinpointing blockages is an easy, intuitive process.

Condition Assessment

Knowing issues in your supply is the first step for you to understand the overall health of your network. Together, Swasth AI and the Endobot Water line-up cover every aspect of your pipeline health to help you plan your maintenance in a comprehensive, analytics-driven manner.

Leak Detection

Despite being small, pipeline leaks can become process bottlenecks and affect operational costs. That’s why the quick, accurate leak-pinpointing abilities of Endobot90 and Endobot120 are key for keeping leaks in your supply pipelines in check.

Contamination Check

Contaminations are hard to locate. Left unchecked, they can drastically impact supply-transmission quality, or turn into a network-wide issue. That’s why the imaging and processing power of the Endobot Water line-up are the perfect safeguards against contamination issues.

Illegal Connections

Illegal connections not only affect supply pressure, but also can have long-term impacts on the structural integrity of connections. That’s why the Endobot water line-up comes equipped with sensors for laser profiling and gradient measurement.

Blockage Pinpointing

Blockage is the most common problem that disrupts flow in supply pipelines. When left unchecked, they not only create transmission issues, but can impact the overall network by creating pressure differentials. But with the Endobot Water line-up, pinpointing blockages is an easy, intuitive process.

Condition Assessment

Knowing issues in your supply is the first step for you to understand the overall health of your network. Together, Swasth AI and the Endobot Water line-up cover every aspect of your pipeline health to help you plan your maintenance in a comprehensive, analytics-driven manner.

Leak Detection

Despite being small, pipeline leaks can become process bottlenecks and affect operational costs. That’s why the quick, accurate leak-pinpointing abilities of Endobot90 and Endobot120 are key for keeping leaks in your supply pipelines in check.

Contamination Check

Contaminations are hard to locate. Left unchecked, they can drastically impact supply-transmission quality, or turn into a network-wide issue. That’s why the imaging and processing power of the Endobot Water line-up are the perfect safeguards against contamination issues.

Illegal Connections

Illegal connections not only affect supply pressure, but also can have long-term impacts on the structural integrity of connections. That’s why the Endobot water line-up comes equipped with sensors for laser profiling and gradient measurement.

Blockage Pinpointing

Blockage is the most common problem that disrupts flow in supply pipelines. When left unchecked, they not only create transmission issues, but can impact the overall network by creating pressure differentials. But with the Endobot Water line-up, pinpointing blockages is an easy, intuitive process.

Condition Assessment

Knowing issues in your supply is the first step for you to understand the overall health of your network. Together, Swasth AI and the Endobot Water line-up cover every aspect of your pipeline health to help you plan your maintenance in a comprehensive, analytics-driven manner.

HVAC Lines

Difficulty in access makes maintenance of HVAC Lines even more difficult. But our robotics are more than capable of navigating such lines and helping you locate problems before they become big.

Fire Hydrants

Due to their critical role in infrastructure, Fire Hydrants need a supply network that will not fail even in worst-case scenarios. Our Inspection Services will help you ensure just that.

Ad Hoc Maintenance

Below the ground, between the walls, or above the ceiling. Any pipe that’s a key part of your infrastructure can be inspected and maintained with the help of our robotic services.

Blockage Detection

Blockage detection is key in sewers for preventing backups, overflow, flooding, contamination, and many other issues...

Condition Assessment

Complexity of factors affecting structural degradation and length of sewer networks make condition assessment even more important...

Post-desilting Check

Desilting is a complex process. This is true especially from an operations perspective...

Pre-commissioning Audit

Test runs are crucial to confirm the functionality of new sewer networks. But ensuring this is hard...

Leak Detection

Despite being small, pipeline leaks can become process bottlenecks and affect operational costs...

Contamination Check

Contaminations are hard to locate. Left unchecked, they can drastically impact supply-transmission quality...

Illegal Connections

Illegal connections not only affect supply pressure, but also can have long-term impacts...

Blockage Pinpointing

Blockage is the most common problem that disrupts flow in supply pipelines...

Condition Assessment

Knowing issues in your supply is the first step for you to understand the overall health of your network...

Proactive Pipeline Inspections for Industries: Prevent Failures, Save Costs

Waiting for a problem to arise before inspecting your pipelines is a costly mistake. Leaks, contamination, unplanned downtime, and compliance issues can shut down operations and damage your reputation. Instead, take control with a proactive inspection strategy. By identifying issues early, you can prevent failures, cut repair costs, minimize downtime, and extend the life of your infrastructure.

- Prevent Costly Pipeline Failures Before They Happen

- Significantly Reduce Emergency Repair Costs

- Minimize Operational Downtime

- Ensure Regulatory Compliance & Environmental Safety

- Make Smarter, Data-Driven Maintenance Decisions

Advanced Add-on Sensors

Options for laser profiling and gradient measurement

Precise Imaging Capability

HD cameras that provide crystal-clear feeds of pipeline interiors

For Multiple Pipelines

Robotics that can access pipelines of diameters ranging from 70mm to 2100mm

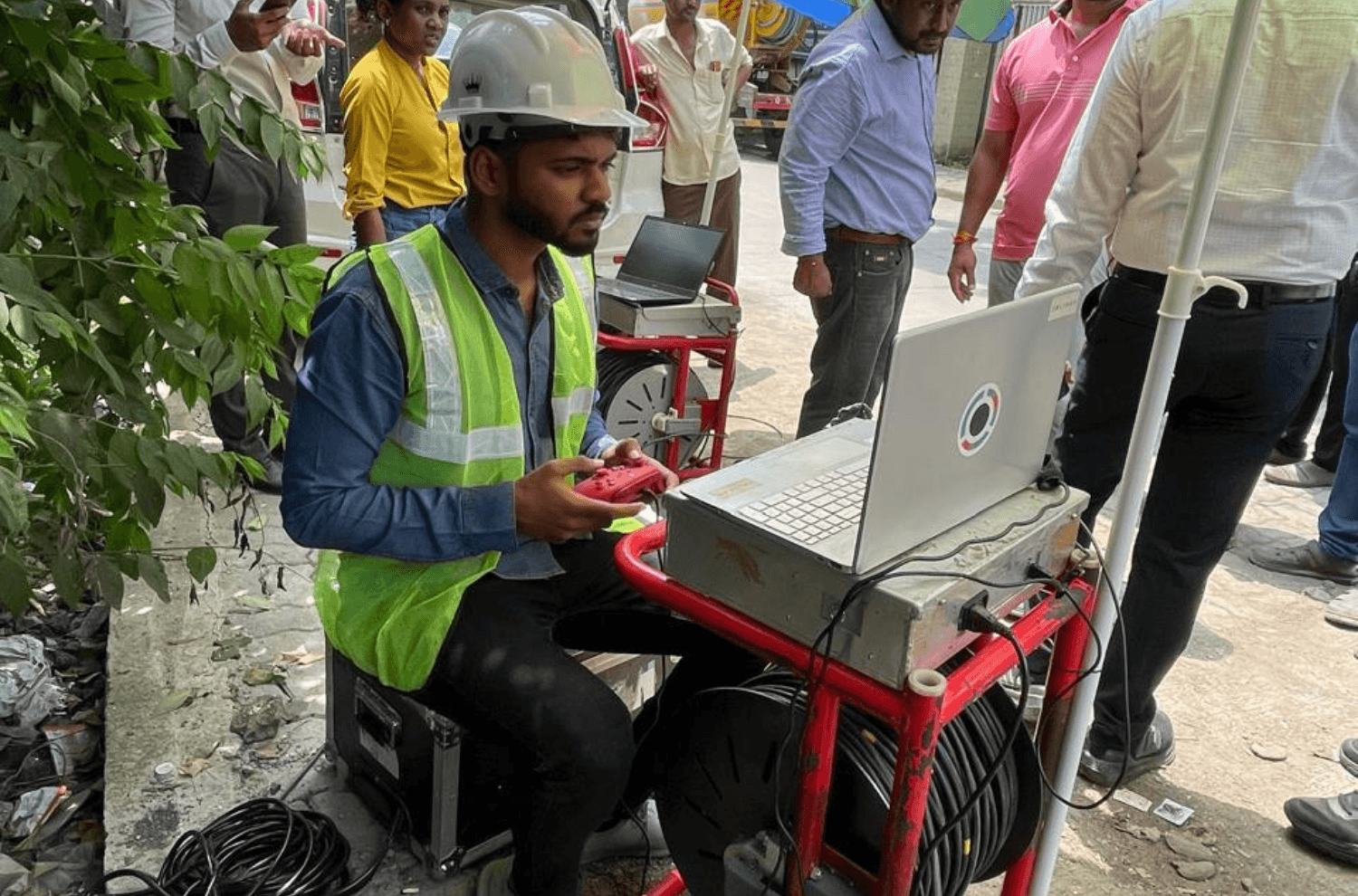

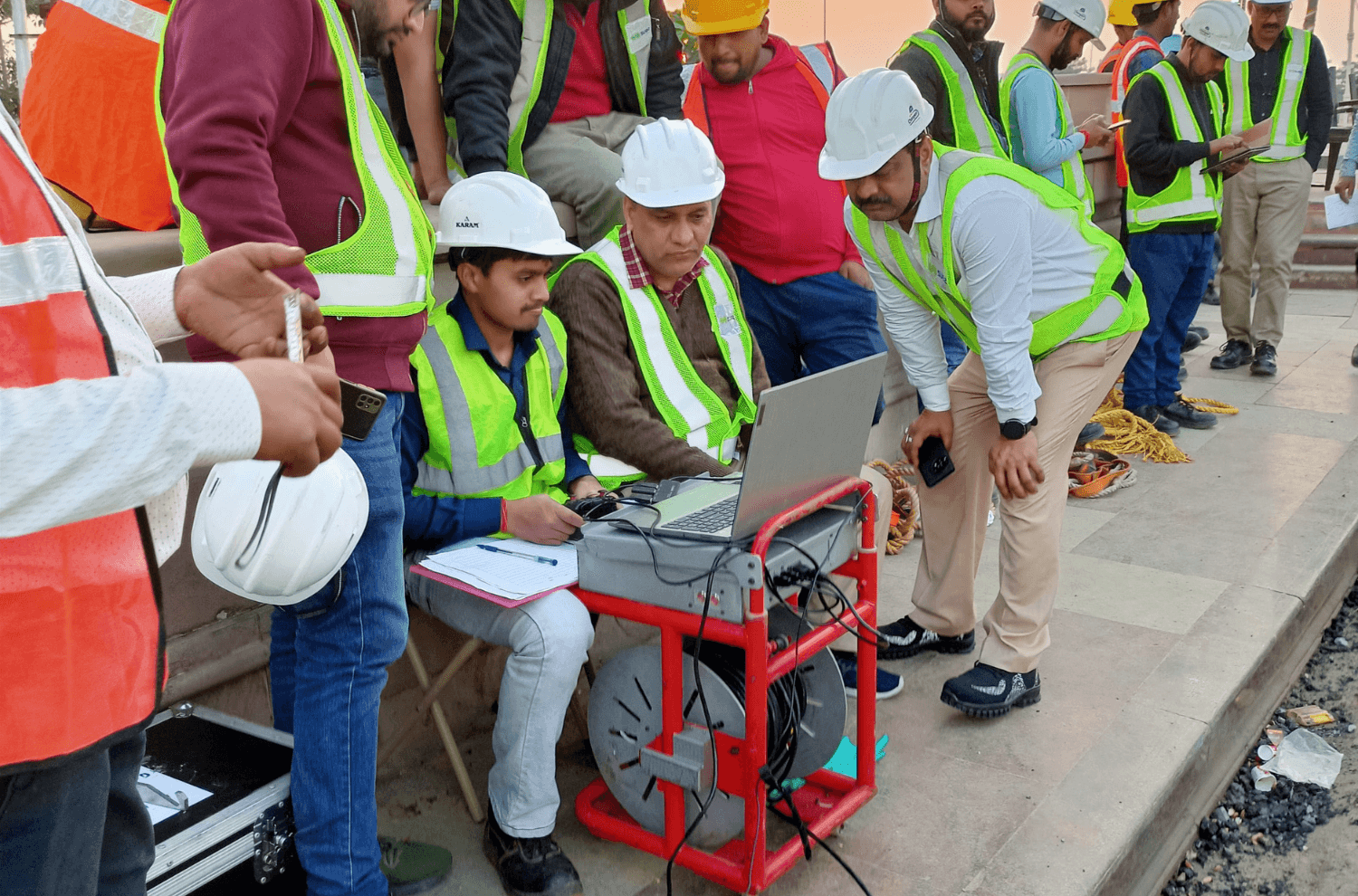

Live Monitoring System

Get a real-time feed of all activity inside your pipeline network

AI-based Defect Detection

Swasth AI makes the process of categorizing and grading defects faster

Instant Report Generation

Access comprehensive insights documented as per WRC guidelines

Dedicated Project Liaison

Our personnel will be a line of contact throughout the project

Flexible Project Contracts

Project-based or distance-based, we tailor service contracts as per your needs

Industry Showcase

Products Deployed: Endobot90, Endobot250, Swasth AI

Assist Veolia reduce contaminations & blockages

Defect detection time reduced by 7 hours

Problem resolution ensured within 24 hours

Digitized 45km of pipelines

Identified 500 defects, 90 contaminations, 55 blockages, and 120 leakage points

Industry Showcase

Maintaining water supply pipelines

Reduced inspection duration from 3 days to 1 day

5-fold reduction in cost and pits dug

Water access restored to 700 houses and 3,700 people

Industry Showcase

Under Namami Gange program, help Suez improve Gomti River’s water quality

- Improved sewage flow from three wastewater-treatment plants

- Defect detection time reduced from 3 days to 4 hours

- 70-plus manholes inspected

- 2-3 blockages detected every day

Industry Showcase

Maintaining water supply pipelines

Reduced inspection duration from 3 days to 1 day

5-fold reduction in cost and pits dug

Water access restored to 700 houses and 3,700 people

Industry Showcase

Assist Veolia reduce contaminations & blockages

Defect detection time reduced by 7 hours

Problem resolution ensured within 24 hours

Digitized 45km of pipelines

Identified 500 defects, 90 contaminations, 55 blockages, and 120 leakage points

Industry Showcase

Products Deployed: Endobot120, Endobot250, Endobot600, Swasth AI

Under Namami Gange program, help Suez improve Gomti River’s water quality

- Improved sewage flow from three wastewater-treatment plants

- Defect detection time reduced from 3 days to 4 hours

- 70-plus manholes inspected

- 2-3 blockages detected every day

Initial

Assessment

We understand your pipeline layout and problem area

On-site Deployment

Our team deploys our robotics at your site to execute your project

Problem Identification

Our robots cover your pipeline network and pinpoint all defects

AI-based Report Generation

You receive a comprehensive report with recommendations

Sewer Pipeline

Fire Hydrants

Municipal Corporations

Manufacturing

Automotives

Real Estate

Pharmaceuticals

Oil & Gas

Mining & Minerals

Food & Beverage

Chemical Processing

Construction

Petrochemicals

Steel & Iron

Special Economic Zone (SEZ)

Airports

State Infrastructure

| Our Clients